The Thomas Scott Process Management System is a comprehensive solution that streamlines the workflow from manufacturing to dispatch. It allows users to input data at each stage of production, review and approve processes, and track real-time updates. With built-in data analytics, the system enables efficient monitoring and optimization of production and dispatch operations.

Key Challenges

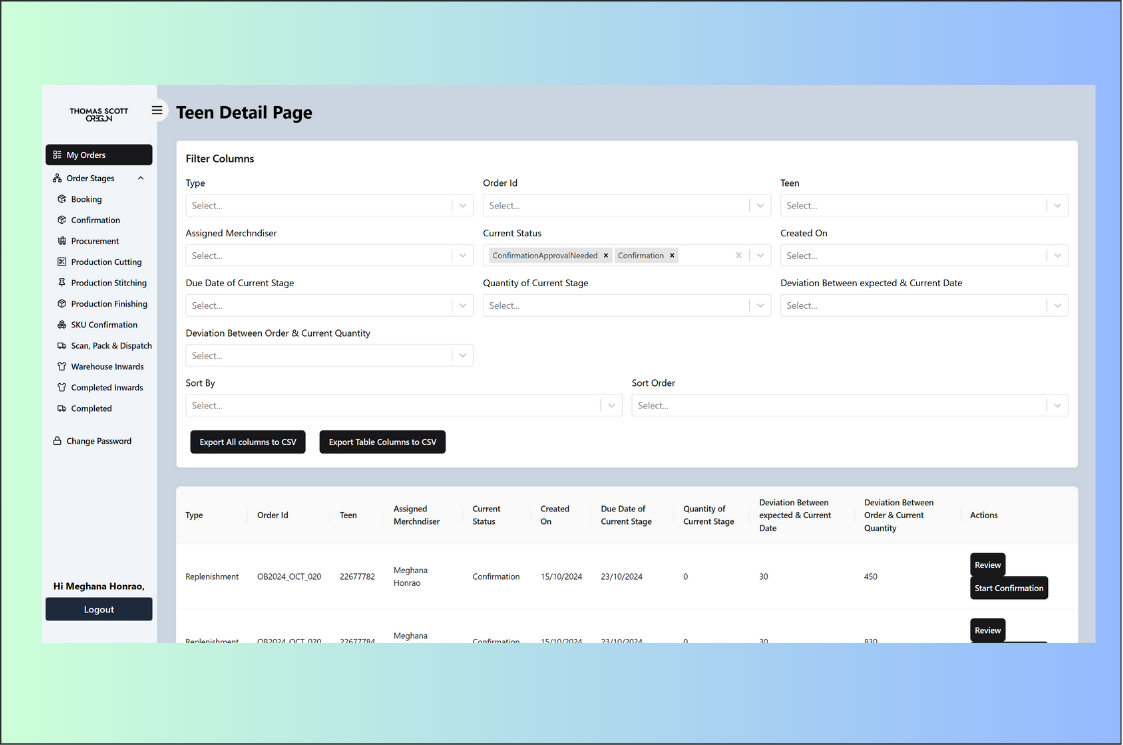

Complex Workflow Management: The client required a system to handle each stage of the manufacturing process, ensuring smooth transitions from one phase to the next.

Real-Time Order Tracking: The need for up-to-the-minute updates on orders, ensuring visibility at every stage of production.

Data-Driven Decision Making: Users needed easy access to data to analyze raw material usage, turnaround times, and pricing to optimize production efficiency.

Manual Process and Delays: The manual review and approval process for each production stage led to delays and inefficiencies in the workflow.

Our Contribution

Stage-Based Workflow: Developed a process where each stage of production is clearly defined, with user input and submission for review and approval at every step. Automated the review and approval process, ensuring faster transitions between stages and reducing delays.

Real-Time Updates: Implemented a live tracking system that provides up-to-date order status, allowing the client to monitor progress at any given time.

Data Analysis Tools: Incorporated tools for users to analyze key metrics such as raw material usage, turnaround times, and pricing to improve operational efficiency.